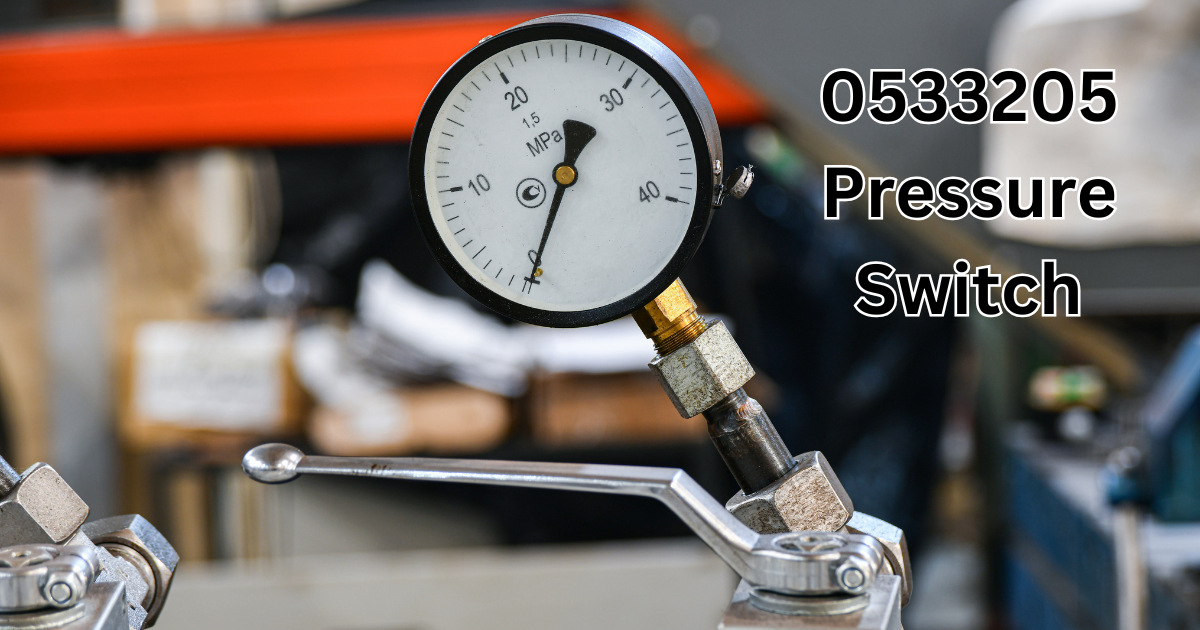

The 0533205 pressure switch stands as a versatile and robust component widely used across industries. Known for its durability and precision, this switch plays a pivotal role in monitoring and controlling pressure systems. Whether you’re in manufacturing, HVAC, or automotive sectors, understanding its functions and benefits can enhance your operations.

What is the 0533205 Pressure Switch?

The 0533205 pressure switch is an electromechanical device designed to monitor and control pressure levels in fluid or gas systems. By activating or deactivating circuits based on preset pressure thresholds, this switch ensures system efficiency and prevents potential damage caused by overpressure or underpressure.

Key specifications of the 0533205 pressure switch include:

- Pressure Range: Accommodates a variety of industrial requirements.

- Material Durability: Constructed to withstand harsh environments.

- Precision Control: Delivers reliable and accurate performance.

How Does the 0533205 Pressure Switch Work?

At its core, the 0533205 pressure switch relies on a pressure-sensitive diaphragm or piston. When pressure exceeds or falls below the set range, the internal mechanism triggers an electrical contact. This response either opens or closes a circuit, enabling the system to maintain optimal pressure levels.

Key Components Include:

- Diaphragm or Bellows: Sensitive to pressure changes.

- Adjustable Set Points: Allow users to define operating thresholds.

- Electrical Contacts: Facilitate signal transmission to external systems.

Applications of the 0533205 Pressure Switch

The adaptability of the 0533205 pressure switch makes it a preferred choice across diverse applications:

Industrial Automation

Used extensively in factories, the switch ensures machinery operates within safe pressure ranges, reducing downtime and maintenance costs.

HVAC Systems

This pressure switch is vital in controlling air flow, refrigerant pressure, and system efficiency in heating, ventilation, and air conditioning systems.

Automotive Industry

From brake systems to fuel injection, the switch supports precise pressure monitoring to enhance vehicle safety and performance.

Oil and Gas Sector

Ideal for monitoring pipelines, compressors, and drilling equipment, the 0533205 switch provides reliability in high-pressure environments.

Advantages of the 0533205 Pressure Switch

The 0533205 pressure switch boasts numerous advantages that make it indispensable in various sectors:

- Reliability: Delivers consistent performance under demanding conditions.

- Customizable Settings: Allows for tailored operations based on specific requirements.

- Compact Design: Easy to integrate into complex systems.

- Durability: Resistant to corrosion, wear, and extreme temperatures.

- Energy Efficiency: Helps conserve energy by optimizing system operations.

How to Choose the Right 0533205 Pressure Switch for Your Needs

When selecting a 0533205 pressure switch, consider the following factors:

Pressure Range

Ensure the switch matches the operational pressure requirements of your system.

Material Compatibility

Verify that the switch’s materials are resistant to the fluids or gases it will encounter.

Electrical Specifications

Check the voltage and current ratings to ensure compatibility with your control system.

Environmental Conditions

Opt for switches designed to withstand the environmental stresses they’ll face, such as temperature extremes or humidity.

Installation Tips for the 0533205 Pressure Switch

Proper installation is crucial to the performance and longevity of the 0533205 pressure switch. Follow these steps for optimal results:

- Positioning: Mount the switch in an accessible location for easy adjustments and maintenance.

- Calibration: Set pressure thresholds accurately to match system requirements.

- Sealing: Ensure connections are leak-proof to prevent contamination.

- Testing: Verify the switch operates correctly under normal and extreme conditions.

Maintenance Best Practices

To keep the 0533205 pressure switch functioning at peak performance, follow these maintenance tips:

- Regular Inspections: Check for wear, corrosion, or leaks.

- Cleaning: Remove debris and contaminants from the diaphragm and connections.

- Calibration Checks: Periodically verify the accuracy of pressure settings.

- Component Replacement: Replace worn parts promptly to prevent system failures.

Common Issues and Troubleshooting

While the 0533205 pressure switch is highly reliable, occasional issues may arise. Here’s how to address them:

Erratic Pressure Readings

- Inspect for diaphragm damage or debris interference.

- Recalibrate the switch to restore accuracy.

Failure to Activate

- Ensure electrical connections are secure.

- Check the pressure setting against actual system pressure.

Leakage

- Tighten fittings and replace damaged seals.

Why Choose the 0533205 Pressure Switch for Your Operations?

The 0533205 pressure switch combines precision, durability, and adaptability, making it a valuable asset in maintaining safe and efficient systems. Its versatility across industries ensures it meets the diverse demands of modern applications.

FAQs

What is the purpose of the 0533205 pressure switch?

The switch monitors and controls pressure in fluid or gas systems, preventing damage caused by pressure fluctuations.

Can the 0533205 pressure switch handle extreme temperatures?

Yes, it is built with materials designed to withstand harsh environmental conditions.

Is the 0533205 pressure switch suitable for outdoor applications?

Absolutely, provided the specific model includes weather-resistant features.

How often should the 0533205 pressure switch be maintained?

Regular inspections should be conducted every 6-12 months, depending on the application.

Can I adjust the pressure settings on the 0533205 pressure switch?

Yes, most models allow for easy customization of pressure thresholds.

Where can I purchase the 0533205 pressure switch?

It’s available through industrial supply stores, online marketplaces, and authorized distributors.

Conclusion

The 0533205 pressure switch is a vital tool for ensuring the safety and efficiency of pressure-dependent systems. By understanding its features, applications, and maintenance requirements, you can maximize its potential and extend its service life. Whether you’re managing industrial machinery or optimizing HVAC systems, this switch is a reliable choice that delivers exceptional value.